When it comes to industrial applications, rubber is far more than just a flexible material. From mining and construction to automotive and manufacturing, the performance of rubber components directly impacts operational efficiency, safety, and long-term costs. But what truly determines how well a rubber product performs? The answer lies in rubber compounding.

At AUP Rubber, we understand that high-quality rubber products start with precise formulation. As experienced rubber compounders in Australia, we specialise in developing custom solutions that meet demanding industry requirements. Whether your application requires high heat resistance, chemical stability, or extreme durability, the compounding process is what makes the difference.

What Is Rubber Compounding?

Rubber compounding is the science and art of blending raw rubber with carefully selected ingredients to achieve specific physical and chemical properties. Raw rubber alone does not provide the strength, resilience, or resistance required for industrial use. Through compounding, additives such as fillers, curing agents, plasticisers, antioxidants, and stabilisers are introduced to enhance performance.

This is where expertise matters. Professional rubber compounders evaluate the environment, load conditions, temperature exposure, and regulatory requirements before developing the right formula. The result is a high-performance industrial rubber product tailored to your application.

1. Performance: Engineered for Demanding Applications

Strength and Load Capacity

Industrial environments demand materials that can withstand constant stress. Reinforcing fillers such as carbon black or silica improve tensile strength and tear resistance. In mining and heavy machinery, this ensures rubber components perform reliably under heavy loads.

At AUP Rubber, our advanced rubber compounding process ensures each product is engineered to deliver maximum structural integrity without compromising flexibility.

Flexibility and Elastic Recovery

Some applications require rubber to stretch, compress, and return to its original shape repeatedly. Poor compounding can lead to cracking or permanent deformation. A carefully balanced formulation ensures optimal elasticity, which is essential for seals, gaskets, and vibration isolators.

Our custom rubber moulding services ensure that components not only fit precisely but also maintain consistent performance over time.

Chemical and Environmental Resistance

Industrial rubber components are often exposed to oils, fuels, solvents, UV rays, and ozone. Without proper compounding, materials may swell, degrade, or fail prematurely.

By incorporating specialised polymers and stabilising agents, we produce industrial rubber compounds that resist harsh environments. This translates into fewer failures, less downtime, and reduced replacement costs for your business.

2. Durability: Extending Product Lifespan

Durability is not just about strength—it’s about maintaining performance over years of operation.

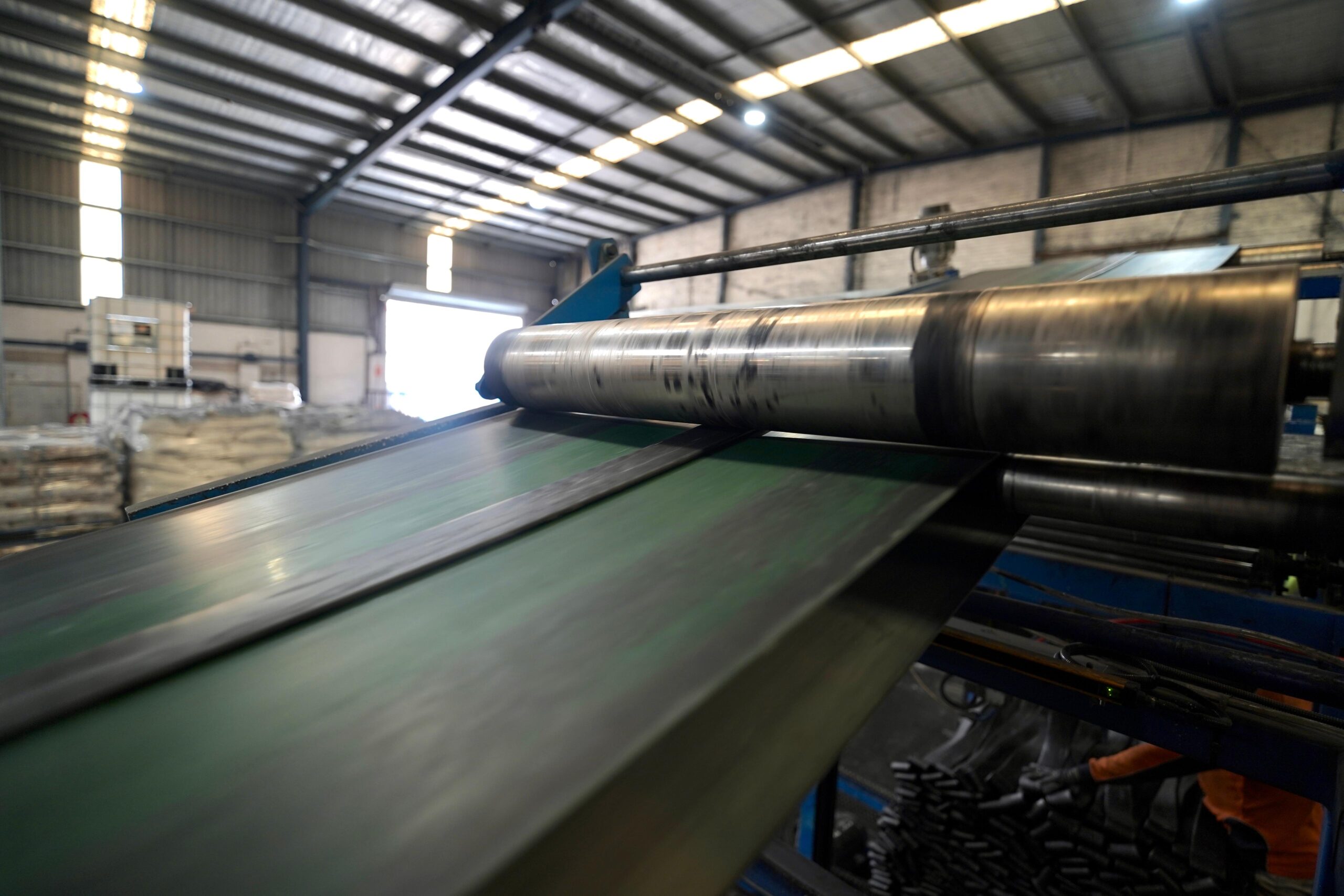

Abrasion Resistance

In industries such as construction and mining, constant friction can quickly wear down inferior rubber materials. Strategic filler selection during the rubber compounding process significantly improves abrasion resistance.

This means longer service life for conveyor components, rollers, and heavy-duty equipment parts.

Heat and Aging Resistance

Heat accelerates rubber degradation. Over time, oxidation and thermal stress can cause brittleness and cracking. High-quality compounds include antioxidants and stabilisers that slow aging and extend product life.

At AUP Rubber, our team designs compounds that withstand Australian climate conditions, ensuring long-term reliability.

Fatigue Resistance

Repeated compression and flexing can cause micro-cracks that eventually lead to failure. Properly engineered compounds maintain structural integrity even after thousands of cycles. This is particularly important in automotive and machinery applications.

Through precision rubber moulding, we ensure that finished components distribute stress evenly, enhancing fatigue resistance.

3. Compliance: Meeting Industry Standards

Compliance is a major concern across industries. Regulations surrounding safety, environmental impact, and product quality continue to evolve.

Environmental Responsibility

Modern manufacturing requires responsible material selection. Certain chemicals and heavy metals are restricted under environmental guidelines. Professional rubber compounders must carefully select ingredients that meet these requirements without compromising performance.

AUP Rubber follows industry best practices to ensure compounds meet Australian standards and environmental regulations.

Industry-Specific Certifications

Different sectors require different performance benchmarks:

- Automotive parts must meet strict safety and durability standards

- Food-grade rubber must comply with hygiene regulations

- Construction materials may require fire-retardant properties

The right rubber compounding process ensures compliance is built into the product from the beginning, avoiding costly redesigns later.

Why Choose Custom Rubber Compounding?

Off-the-shelf rubber solutions may seem cost-effective, but they often fail in demanding industrial environments. Custom compounding allows materials to be precisely engineered for:

- Specific temperature ranges

- Chemical exposure conditions

- Load-bearing requirements

- Regulatory compliance standards

As trusted Australian rubber compounders, AUP Rubber works closely with clients to understand operational needs before developing tailored solutions.

The Role of Rubber Moulding in Final Performance

Compounding creates the material—but rubber moulding shapes it into high-performance components.

Precision moulding ensures:

- Accurate dimensions

- Consistent material density

- Uniform stress distribution

- Reduced production defects

At AUP Rubber, we combine advanced compounding expertise with modern moulding capabilities to deliver reliable industrial rubber products across multiple sectors.

Long-Term Business Benefits

Choosing the right partner for rubber compounding offers measurable advantages:

- Reduced maintenance and downtime

- Longer equipment lifespan

- Improved operational efficiency

- Stronger compliance confidence

- Lower total cost of ownership

Instead of reacting to failures, businesses can operate proactively with materials designed for performance from day one.

Partner with AUP Rubber

When performance, durability, and compliance matter, the quality of your rubber compound makes all the difference. At AUP Rubber, we specialise in high-performance rubber moulding, advanced rubber compounding, and tailored industrial rubber solutions designed for Australian industries.

Our experienced team of rubber compounders works closely with clients to develop custom formulations that meet exact specifications. Whether you require heavy-duty components for mining, specialised seals for manufacturing, or compliant materials for regulated industries, we deliver solutions engineered for long-term success.

Final Thoughts

Rubber compounding is not just a technical process—it is the foundation of product reliability. From improving mechanical strength and environmental resistance to ensuring compliance with industry standards, compounding directly influences performance and lifespan.

If you want rubber products that perform consistently under pressure, investing in expert compounding and precision moulding is essential.

With AUP Rubber, you gain more than a supplier—you gain a trusted partner committed to delivering high-quality, durable, and compliant industrial rubber solutions built to perform in the real world.